How Gas Flow Helps the Laser | Understanding Laser Powder Bed Fusion

While the use of inert gas prevents oxygen interaction, the flow of this gas performs a valuable function as well: It clears the air for the laser. Part of a series of videos on laser powder bed fusion filmed by looking at an open-source additive manufacturing machine.

One of the most important elements of the laser powder bed fusion process is invisible! Inert gas such as argon and nitrogen prevents interaction with oxygen during 3D printing. This is essential for safety in the case of a reactive metal such as titanium, and essential for the success of the build in any metal. Meanwhile, inert gas also plays a valuable mechanical role by clearing plumes or spatter away from the path of the laser beam. This mechanical role played by the flow of the gas in motion is the subject of the video above.

At the Technical University of Denmark (DTU), where researchers have developed an open-source laser powder bed fusion system built from third-party hardware, we filmed a series of videos on the operation of laser powder bed machines — including this video discussing the role of inert gas and its flow through the build chamber.

Welcome! You’ve unlocked premium content.

Transcript

In laser powder bed fusion, one of the most important elements of the system is largely invisible. Flow of gas within the chamber assures the consistency of the laser beam intensity. I'm Pete Zelinski with Additive Manufacturing Media, and I am at the Technical University of Denmark in Copenhagen, where we're looking at an open source laser powder bed fusion system that researchers here have developed.

And among other things, our time with this machine gives us a chance to explain some of the basic, fundamental elements of how laser powder bed fusion works.

One of those basic elements is inert gas that fills the build chamber. During metal 3D printing through laser powder bed fusion, the chamber needs to be filled with an inert gas. Could be argon, could be nitrogen depending on the metal being 3D printed, but it performs the important function of preventing the part from reacting with oxygen as it's being 3D printed.

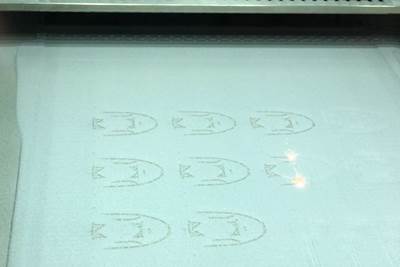

Meanwhile, that inert gas is also pressed into another important function. Laminar flow of the gas across the build chamber clears the air to give the laser beam a clear view of, a clear shot at the powder bed. So that laser beam is traveling all through the powder bed, and it is melting the metal to create the geometry of the part needed at that particular layer.

And that melting produces some secondary effects. There can be plumes, there could be spatter. Any of these effects has the chance of getting in the way of the laser beam. Maybe changing the intensity of the beam that arrives at the powder bed.

So to prevent that, to assure that the beam intensity is consistent, flow of gas blows away these effects, these obstacles that could get in the way of the laser beam. For this to work as it should, the ideal case is for this gas flow to be weak close to the powder bed but much stronger a little above it to provide a shielding barrier.

And then up above, closer to the lens, you can see where airflow is created by this venting system here.

By the way, why is the inert gas so important? Here is an unintended picture of that importance. This part had to be scrapped because the nitrogen gas ran out halfway through the 3D printing build. And you can see the precise layer where the nitrogen went away.

Oxygen took its place. Oxidation of the metal began at that point. To the extent that there are different material properties starting at the layer where oxidation set in.

We are posting more videos like this. Looking at fundamental components of a laser powder bed fusion machine. Find those other videos in this series in links in the description, and also find a link to our report about this work. The development of this open source laser powder bed fusion system.

We also have a lot of material about getting started with additive manufacturing. The basics of additive manufacturing. Find that at GBM.Media/AM101.

Related Content

3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

Read MoreThe Downloadable Metal 3D Printer

Copenhagen researchers introduce a fully open-source laser powder bed fusion system, now available on GitHub. This release follows their development of an open-source vat polymerization machine. Here is the purpose and promise of this philanthropically funded effort to advance AM application and adoption.

Read MoreAdditive Manufacturing Versus Cavitation

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.

Read MoreTwo 12-Laser AM Machines at Collins Aerospace: Here Is How They Are Being Used

With this additive manufacturing capacity, one room of the Collins Iowa facility performs the work previously requiring a supply chain. Production yield will nearly double, and lead times will be more than 80% shorter.

Read MoreRead Next

What Is a Galvanometer? | Understanding Laser Powder Bed Fusion

The “galvo” steers the laser beam. Part of a series of videos on laser powder bed fusion filmed by looking at an open-source additive manufacturing machine.

Read MoreWhat is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

Read MoreThe Downloadable Metal 3D Printer

Copenhagen researchers introduce a fully open-source laser powder bed fusion system, now available on GitHub. This release follows their development of an open-source vat polymerization machine. Here is the purpose and promise of this philanthropically funded effort to advance AM application and adoption.

Read More