What Is a Galvanometer? | Understanding Laser Powder Bed Fusion

The “galvo” steers the laser beam. Part of a series of videos on laser powder bed fusion filmed by looking at an open-source additive manufacturing machine.

Scroll to unlock this premium content if video does not play.

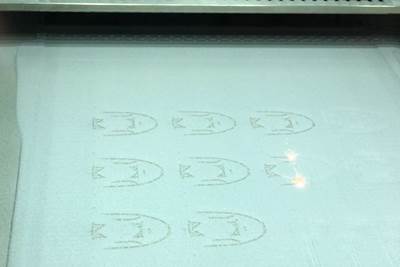

In a laser powder bed fusion (LPBF) additive manufacturing machine, the galvanometer, or “galvo,” is the hardware element using coordinated mirror motion to precisely steer the laser beam. The laser itself is fixed, but its beam is in motion thanks to the galvo. A laser beam following a seemingly simple and continuous path through a powder bed, to melt the metal along that path, is probably in fact responding to complex set of precise angular moves of multiple mirrors reflecting the beam from one mirror to another.

Welcome! You’ve unlocked premium content.

At the Technical University of Denmark (DTU), where researchers have developed an open-source laser powder bed fusion system built from standard third-party hardware, we filmed a series of videos on fundamental elements of laser powder bed fusion — including this video that takes a look at the galvanometer and the important role it plays.

Transcript

I'm at the Technical University of Denmark in Copenhagen, where researchers have developed an open source laser powder bed fusion machine, and among other things, it gives us a chance to look at and explain fundamental elements of a laser powder bed fusion system. A Galvo, or galvanometer, is fundamental to the operation of laser powder bed fusion.

The galvo moves the laser beam, moves the beam through the bed of powder metal. The laser itself is stationary in the machine, but the laser beam passes through the galvo, which moves it using a set of coordinated moving mirrors. In its most simple form, one mirror moves the beam in the X direction, another mirror moves it in the Y direction, and together these coordinated moving mirrors in the galvo create the path the laser beam follows to 3D print precisely the part profile needed at a given layer.

One issue, the galvo locates in the center of the top of the build chamber and this means that the angle of the beam changes as it traces its path through the powder bed. And so you would expect that the shape of the laser spot would also change with that changing beam angle.

A perfect circle directly below the galvo becoming an increasingly more distorted oval as the angle of the beam increases. To compensate for that is the purpose of this f-theta lens.

The lens geometry overcomes exactly that distortion resulting from the angle of the beam. It's not perfect. There is still some spot size discrepancy that users of laser powder bed fusion need to understand, but in general, the combination of galvo plus the right lens geometry allows for consistent laser beam intensity as the beam traces the precise path it needs to trace through the powder bed. We are doing other videos like this that look at other components of laser powder bed fusion. Find these other videos in links in the description.

Also find a link to our report about the development of this open source laser powder bed fusion system. And if you're interested in much more on the basics of additive manufacturing, check out GBM.Media/AM101.

Related Content

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreRead Next

How Gas Flow Helps the Laser | Understanding Laser Powder Bed Fusion

While the use of inert gas prevents oxygen interaction, the flow of this gas performs a valuable function as well: It clears the air for the laser. Part of a series of videos on laser powder bed fusion filmed by looking at an open-source additive manufacturing machine.

Read MoreWhat is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

Read MoreThe Downloadable Metal 3D Printer

Copenhagen researchers introduce a fully open-source laser powder bed fusion system, now available on GitHub. This release follows their development of an open-source vat polymerization machine. Here is the purpose and promise of this philanthropically funded effort to advance AM application and adoption.

Read More